自動噴砂房有什么優缺點?

自動噴砂房的核心在于「程序控制」。其采用PLC(可編程邏輯控制器)或工業計算機系統,預設噴槍移動軌跡、磨料流量、噴射壓力等參數。例如,通過機械臂或軌道式噴槍系統,可實現三維空間的精準覆蓋,尤其適用于復雜曲面工件(如汽車輪轂、航空葉片)。自動噴砂房,強調自動化系統可集成除塵、磨料回收等功能,形成閉環處理。

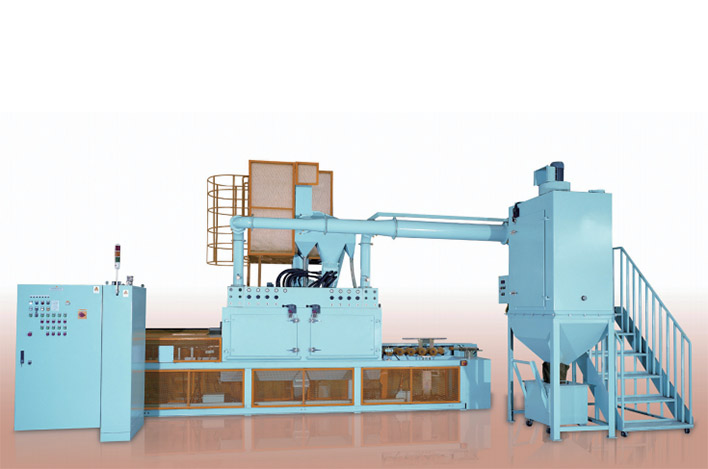

The core of an automatic sandblasting room lies in 'program control'. It adopts PLC (Programmable Logic Controller) or industrial computer system to preset parameters such as spray gun movement trajectory, abrasive flow rate, and spray pressure. For example, precise coverage of three-dimensional space can be achieved through robotic arms or rail mounted spray gun systems, especially suitable for complex curved workpieces such as automotive wheels and aviation blades. Automatic sandblasting room emphasizes that the automation system can integrate functions such as dust removal and abrasive recovery, forming a closed-loop processing.

自動噴砂房通常采用「壓送式」原理:磨料與壓縮空氣在混合室內加壓后,通過管道輸送至噴槍,壓力穩定且噴射力度強(參考B2B平臺數據,典型壓力范圍為0.6-0.8MPa)。部分高端機型還配備磨料自動篩分裝置,可循環使用鋼丸、玻璃砂等材料。

Automatic sandblasting rooms usually use the principle of "pressure delivery": the abrasive and compressed air are pressurized in the mixing chamber and transported to the spray gun through pipelines, with stable pressure and strong spraying force (referring to B2B platform data, typical pressure range is 0.6-0.8MPa). Some high-end models are also equipped with automatic abrasive screening devices, which can recycle materials such as steel balls and glass sand.

手動噴砂房多為「吸送式」設計,依靠文丘里效應將磨料從儲料罐吸入噴槍。百度百家號某技術分析指出,這種方式壓力較低(約0.3-0.5MPa),適合鋁材、木材等軟質基材,但磨料損耗率較高。

Manual sandblasting rooms are mostly designed as "suction type", relying on the Venturi effect to suck abrasives from the storage tank into the spray gun. According to a technical analysis on Baidu Baijiahao, this method has lower pressure (about 0.3-0.5MPa) and is suitable for soft substrates such as aluminum and wood, but has a higher abrasive loss rate.

自動噴砂房的理論效率可達手動操作的3-5倍。某船舶制造企業案例顯示,30平方米的鋼板表面處理,自動系統僅需20分鐘,而手動需2小時以上。這得益于多噴槍同步作業和連續進料系統。

The theoretical efficiency of an automatic sandblasting room can reach 3-5 times that of manual operation. A case study of a shipbuilding enterprise shows that the automatic system only takes 20 minutes for surface treatment of a 30 square meter steel plate, while manual treatment takes more than 2 hours. This is due to the synchronous operation of multiple spray guns and continuous feeding system.

自動化系統通過參數標準化實現Ra值(表面粗糙度)波動范圍≤0.5μm,適合批量生產。某汽車零部件廠商的測試數據表明,自動噴砂后涂層附著力測試合格率提升至99.3%。

The automation system achieves a fluctuation range of Ra value (surface roughness) ≤ 0.5 μ m through parameter standardization, which is suitable for mass production. The test data from a certain automotive parts manufacturer shows that the pass rate of coating adhesion testing after automatic sandblasting has increased to 99.3%.

本文由自動噴砂房友情奉獻.更多有關的知識請點擊:http://www.eoeo8.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.eoeo8.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

魯公網安備 37142502000144號

魯公網安備 37142502000144號